- Home

- Products

- Slitting lines

- Recoilers

- Recoiler with rollers wrapping system

Recoiler with rollers wrapping system

Machine description

The rewinding system is designed to achieve evenly wound coils with uniform tension and allowing additional roll banding and removing the slit coils without delay.

The rewinding system is designed to achieve evenly wound coils with uniform tension and allowing additional roll banding and removing the slit coils without delay.

The machine is composed by:

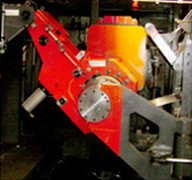

- Main body frame is carbon steel fabricated and tension relief.

- Hydraulically expanded multi-wedge hardened recoiler drum incorporate a integral gripper system and is supported on high precision bearings.

- Automatic threading system with roller clamp and articulated hinge arm.

- Mechanical drive with helical gear box for recoiler drum.

- Coils ejector plate hydraulically operated.

Main characteristics of a representative machine:

| Max. Coil weight | t | 15 |

| Coil outside diameter min/max | mm | 750/1800 |

| Nominal diameter of expanded mandrel | mm | 610 |

| Width of the mandrel | mm | 1400 |

| Max. Recoiler Tension | Kp | 15000 |

| Recoiler speed | m/min | 60 |

Operation sequences:

|

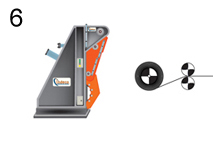

Description:The fonction of this threading system is to wrap the metal strip on the mandrel of recoiler without holding and bending the metal strip end in between of mandrel jaws. The rollers wrapping is wrapping gently the metal strip on the mandrel preventing marks or notches on the sensitive metal surfaces. The main application of this system is for recoiling high quality sensitive metals such aluminium, stainless steel, coatings, etc. And more than that when the quantity of coils is very high and the diameter of them is small. The system is very performant for service centers with high production of small diameter coils. |

|

|

|

|

|

|

|

General technical data:Strip width: 500 a 2100 mm. Strip thickness: 0,1 a 3 mm. Metal types: Aluminium, stainless steel, coatings and brass. |

|

Metal coil slitting, cut to length lines and packaging and stacking lines

- Offices: Avenida de Navarra 24 - 20013 San Sebastian - Guipuzcoa - Espa˝a. Tel:(+34) 943.209.223 - Fax: (+34) 943.209.223

e-mail:cinser@cinser.eu - Manufacturing Plant - Factory: Avenida de la Industria, 56-58, Carretera M-413, km 1,2 - 28970 Humanes de Madrid - Spain. Phone: (+34) 609.484.285 - Fax: (+34) 916.900.735

e-mail:jorge@cinser.eu