- Revamping

- Home

- Revamping

Revamping

-

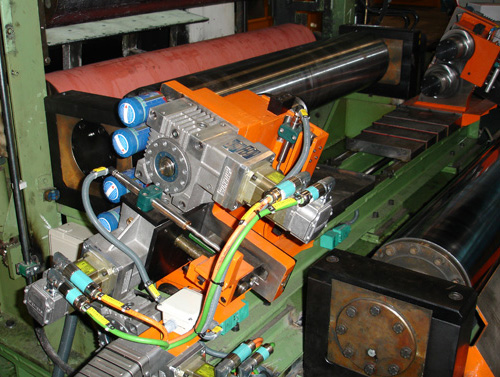

Supply of Fully Automatic Tooling Change Over System for Slitter for Stinless (required time: Less than 5 minutes)

-

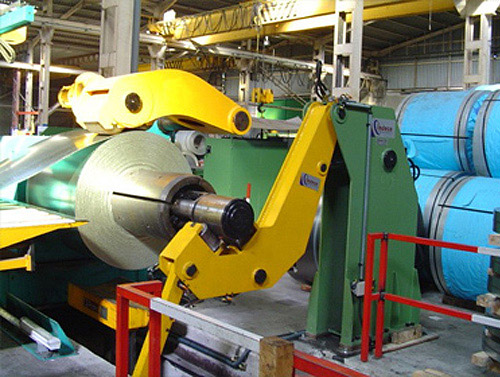

Supply of Decoiler equipped wit Brake Generator for Cut to Length Line

-

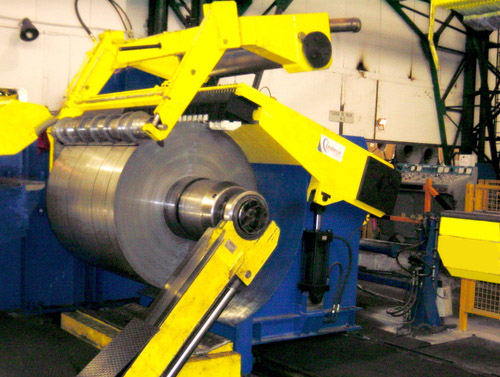

Supply of Outboard Support for a Mandrel for 30 t.

-

Supply of Fully Automatic Tooling Change Over System for Slitter for Carbon Steel (required time: Less than 5 minutes)

-

Supply of a Desplaceable Tension Unit + Rotary Belt Bridle for Slitter for Stainless Steel

-

Supply of a Surface type of Decoiler Unloading Car Unit for Slitter

-

Supply of a Recoiler Unit for 30 t.

-

Supply of an Automatic Splitters Change Over System for Recoiler for Stainless Steel coils

-

Supply of an Automatic Splitters Press Arm System for Recoiler to get high quality coils

-

Supply of a Trims Slitter Unit for Aluminium Film.

-

Supply of Strip Wrapper for Aluminium foil

-

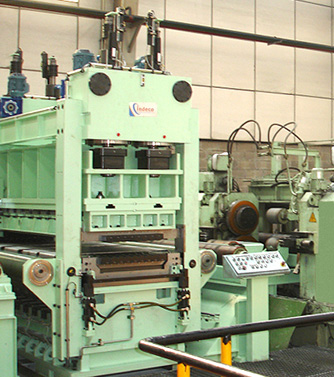

Supply of a Precision Leveller Unit for stainless steel.

-

Supply of a High Speed (90 m/min) Electronic Shear for Cut to Length Line

-

Supply of a Control System Unit in a.c. for Slitter for Stainless Steel at speed of 300 m/min

-

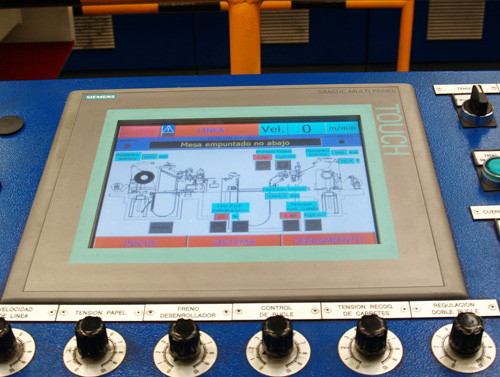

Touch Screen supply for Control Desk for Slitter, Stainless Steel at speed of 300 m/min

-

Supply of Wrapping Unit, fitted with rolls for Aluminium Strip

-

Supply of a Band Wrapper unit for Aluminium Film

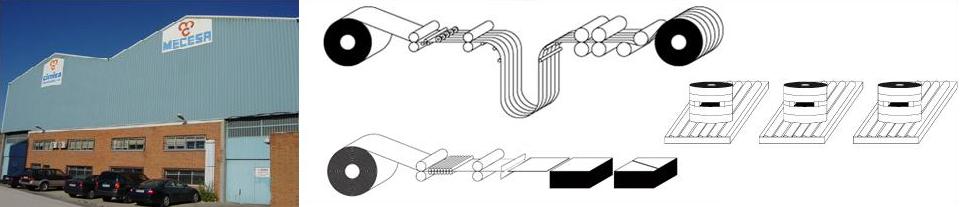

A systematic and periodical modernisation of the Slitting and Cut to Length Lines, CINSER coil processing systems design, is an alternative that customers must consider up versus an investment of a brand new Line.

Machines overhauling and modernisation of Lines can be done for CINSER's manufactured machines and Lines as also from any others.

CINSER's revamping proposal for Lines is based in a progressive and step by step production improvement, which can be measured in Production rates, before and after modernisation. Also maintenance cost shall be reduced and can be measured as well as add value for improvement of the quality of processed metal coils and production rejects reduction and less customer's bad quality claims.

Machining facilities:

Machining center

With a total capacity of 16,075 mm machining in X - horizontal and 3,500 mm in Y - Vertical, is equipped with two milling machines, with the following characteristics:

| Model | CNC | Measures in mm. | Table mm | Admissible weight in kg. | ||

|---|---|---|---|---|---|---|

| X | Y | Z | ||||

| Juaristi MX 7 RAM | Heidenhain TNC 430 M | 11.000 | 3.500 | 1.000 | MG20 Swivel 2.500 x 2.500mm | 20.000 (On the table) |

| Juaristi MX 5 RAM | Heidenhain TNC 430 M | 11.000 | 2.500 | 1.000 | MG12 Swivel 2.000 x 2.000mm | 12.000 (On the table) |

Boring / Milling

| Model | CNC | Measures in mm. | Table mm | Weight in kg. | |||

|---|---|---|---|---|---|---|---|

| X | Y | Z | L | I | |||

| Juaristi | Heidehhain TNC 355 2 Columnas | 1.530 | 2.885 | 4.030 | 2.500 | 2.000 | 30.000 |

| Juaristi | Heidenhain TNC 135 | 1.600 | 1.000 | 1.600 | 1.120 | 1.100 | 3.000 |

| CME | Heidenhain TNC 426 CB | 2.500 | 1.200 | 1.030 | 2.700 | 1.000 | 600 |

| Correa | Heidenhain TNC 410 P | 2.500 | 800 | 800 | 2.500 | 700 | 4.000 |

| Soraluce | Heidenhain TNC 415 B | 4.500 | 1.600 | 900 | 6.000 | 850 | No limit |

Turning machines:

| Model | CNC | Measures in | ||

|---|---|---|---|---|

| Maximum diameter | Maximum Length | |||

| Guruzpe | 8050 TC | 1.500 | 6.000 | |

| Cazeneuve | - | 810 | 4.000 | |

| Nerviˇn | - | 645 | 1.500 | |

| CMZ | - | 420 | 1.000 | |

Other facilities:

- Radial milling machine.

- Plate bending rolls 3000 mm - 15 mm.

- Plate shear machine 15 mm.

- Continous saw.

Metal coil slitting, cut to length lines and packaging and stacking lines

- Offices: Avenida de Navarra 24 - 20013 San Sebastian - Guipuzcoa - Espa˝a. Tel:(+34) 943.209.223 - Fax: (+34) 943.209.223

e-mail:cinser@cinser.eu - Manufacturing Plant - Factory: Avenida de la Industria, 56-58, Carretera M-413, km 1,2 - 28970 Humanes de Madrid - Spain. Phone: (+34) 609.484.285 - Fax: (+34) 916.900.735

e-mail:jorge@cinser.eu