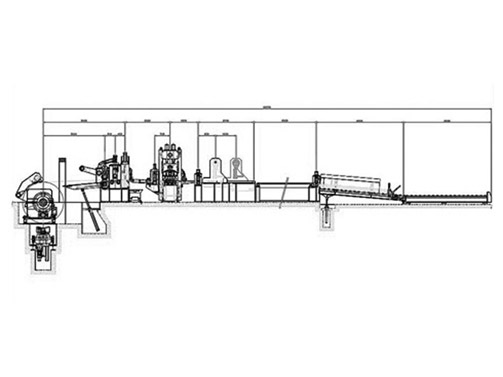

This is an optimised Cut to Length Line with a modular basic design on which can add and fit options for increasing production capacity and performance characteristics of the Line, according customer's specifications and requirements.

This modular design is applied so for mechanical components as for electronics because an integrated "at home" construction, made inside CIMISA's plant.

All control systems are manufactured with elec. standard components, available in the market permitting an easy replacement for maintenance services anywhere at anytime.

The main advantage of this type of modular design for the customer is a present low investment, for a High Quality and Performance Line and a future step by step development according production requirements.

Production Parameters of Cut to Length Line 1500 CL type

Type of material to be processed:

- Carbon steel, Stainless Steel, Aluminium, Non ferrous metals and alloys.

- Cold and hot rolled, pickled, dry or oiled, galvanized and coatings.

| Mechanical characteristics: |

| Material strength |

N/mm² |

maximum |

900 |

| Yield point |

N/mm² |

maximum |

600 |

Coil characteristics: Representative case

| |

|

minimum |

maximum |

| Strip width |

mm |

500 |

1500 |

| Strip thickness |

mm |

2 |

8 |

| Coil O.D. |

mm |

800 |

2000 |

| Coil I.D. |

mm. |

508/610 |

| Coil weight |

t |

- |

25 |

Cut to length line general specifications

Processing speeds

| Strip Threading speed |

| Max. speed for leveller and cutting |

- |

m/min |

15 |

| Line speed |

n░1 |

m/min |

21 |

| Line speed |

n░2 |

m/min |

42 |

Tension Unit (Unwind )

| Strip width maximum mm |

Line speed m/min |

Tension in kg maximum |

| 1500 x 5 |

42 |

3500 |

| 1500 x 8 |

21 |

7000 |

Cutting capacity

| Line speed m/min. |

Strip thickness mm. |

| 0-21 |

≥5 ¸ 8 |

| 0-42 |

≥2 ≥ 5 |

Line design

- Feeding System

- Shear type

Board of production

| |

V1 = 21 m/min |

V2 = 42 m/min |

| Formats length mm |

N║ formats/min |

Speed |

N║ formats/min |

Speed |

| 500 |

38 |

19 |

38 |

19 |

| 1000 |

21 |

21 |

32 |

32 |

| 2000 |

10,5 |

21 |

21 |

42 |

| 3000 |

7 |

21 |

14 |

42 |

| 4000 |

5,25 |

21 |

10,5 |

42 |

| 5000 |

4,2 |

21 |

8,4 |

42 |

| 6000 |

3,5 |

21 |

7 |

42 |

Cut to length line general specifications

| Processing speeds |

minimum |

maximum |

| Formats Length |

mm |

500 |

6000 |

| Formats Width |

mm |

400 |

1500 |

Stacks of Formats

| Weight and height |

| Format weight |

kg/m |

750 |

| Format weight |

kg. |

6000 |

| Stack Height including pallet |

mm |

600 |

Tolerance average

- Length ▒ 0,2 mm

- Diagonal ▒ 0,5 mm

Indicated tolerances and productions are in function and related with following factors:

- Strip Tension stability and fluctuations

- Strip quality and surface smoothness

- External factors such electromagnetism and mechanical vibrations

Machine operator skill

| Pressure |

10% |

5% |

| Three-phase feed pressure |

380 V. |

50 Hz. |

| Auxiliary Elec. current |

110 V. |

50 Hz. |

Compressed air

Hydraulic power pack

| Nominal Pressure |

bars. |

| Nominal Pressure |

100 bars. |

| Maximum Pressure |

110 bars. |

| Cooling system by |

Air |

Climatic condition

| Temperature |

minimum |

maximum |

| Outdoor temperature |

- 6░C |

+ 44░C |

| Indoor temperature |

+ 5░C |

+ 40░C |