- Home

- Products

- Slitting lines

- High Production Slitting Line, HPS type

High Production Slitting Line, HPS type

-

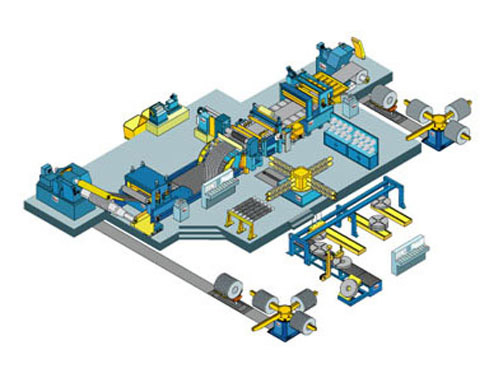

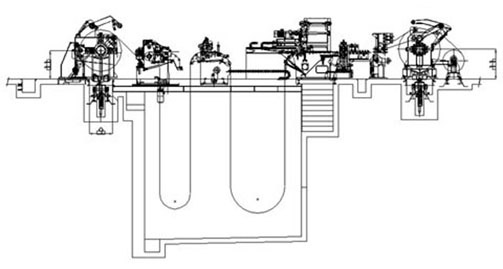

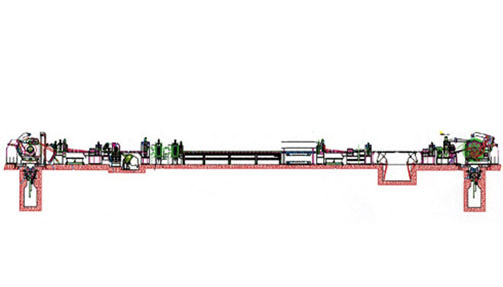

High Production Slitting line HPS type

-

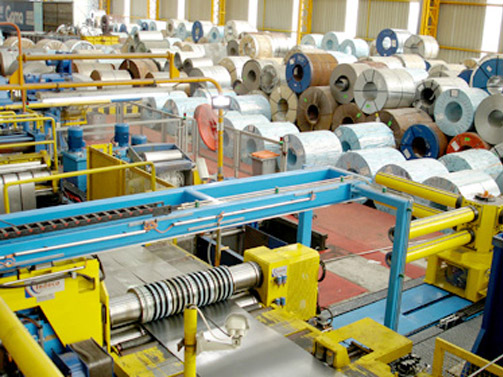

High production Slitting Line HPS type of 1500 mm x 8mm x 150 m/min

-

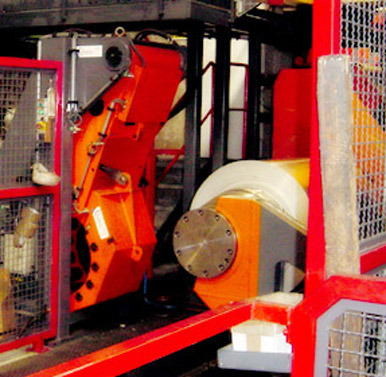

Slit coils exit with four arms capstan

-

Slitting Line of 1500 mm. x 6 mm. x 200 m/min

-

Slitting line for stainless steel of 1500 mm x 3 mm x 150 m/min

-

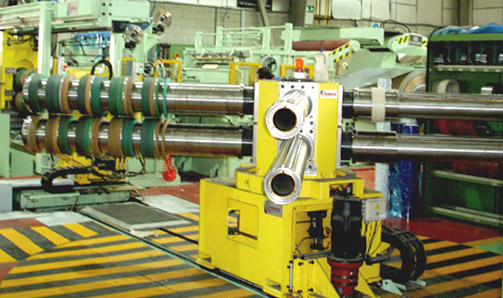

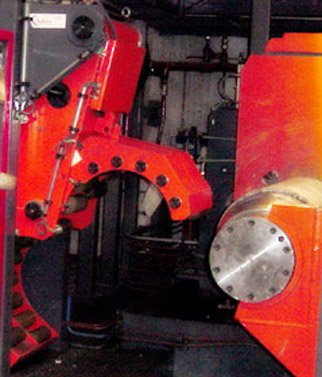

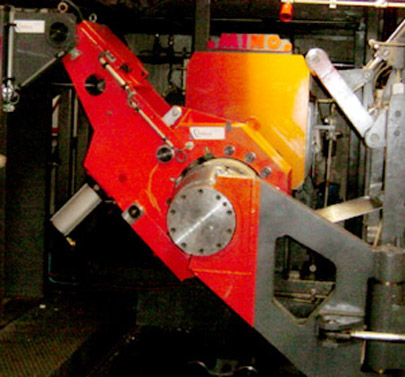

Slitter automatic tool change

-

High performance Slitting Line of 1.250 mm x 0,1 up to 3 mm of thickness x 350 m/min

-

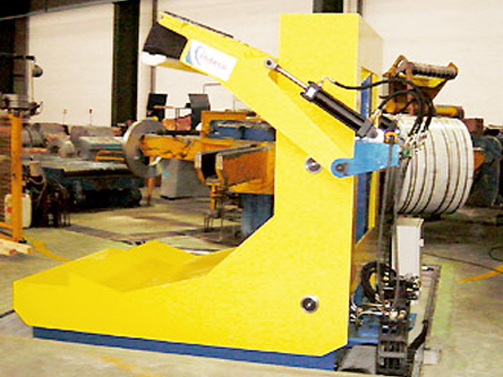

Slit coil exit car

-

High performance Slitting Line for stainless steel of 0,1 up to 3 mm thickness x 1.500 mm width

-

Slitting line for stainless steel of 1500 mm x 3 mm x 150 m/min

-

Automatic treading machine for aluminium at stand by position

-

Automatic threading machine for aluminium at travelling position.

-

Automatic threading machine for aluminium at travelling position.

-

Slitting line view

-

Decoiler & Inlet area of Slitter for stainless strip 1500 x 3 mm

-

High production Scrap baler unit for slitting line.

-

Decoiler & Inlet area of Slitter for stainless strip 1500 x 3 mm

-

Slitter automatic tool change

-

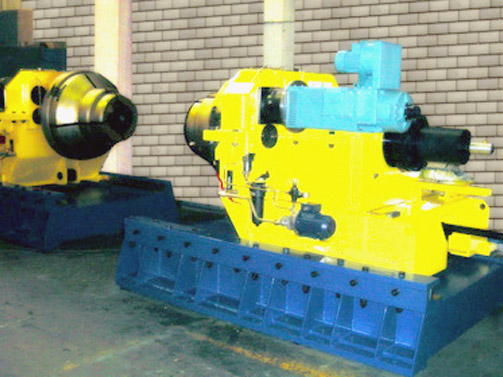

Double decoiler for 40 t and strip thickness of 15 mm.

-

Hydraulic Decoiler for 40t. Weight x 2000mm. x 10mm. For Stainless Steel.

-

Hydraulic Decoiler for 40t. Weight x 2000mm. x 10mm. For Stainless Steel.

-

Rotary Belt Bridle & Displaceable Tension unit for stainless strip 1500x3 mm

-

Surface type rolling Car on Recoiler for stainless strip 1500x3 mm

-

Surface type rolling Car on Recoiler for stainless strip 1500x3 mm

-

High Production Slitting line HPS type

-

Haute Production Ligne type HPS plane

- Line Parameters:

- Coil weight up to 40 t.

- Strip width up to 2100 mm. and more.

- Strip thickness range from 0,05 up to 15 mm.

- Line speed up to 500 m/min.

- Production rate:

- 190.000 t./year and more according production mix.

- Processing materials:

- Carbon Steel, Stainless Steel, Aluminium, non ferrous metals and alloys.

- Cold and hot rolled coils, dry, oiled, galvanized and coatings.

- Material strengths of more than 1200 N/mm2 with yield up to 1000 N/mm²

- Decoiler:

- Coil inside diameter of 508 and 610 mm. and more.

- Alimentación automática de bobinas con posicionado de altura de la bobina.

- Con sistema automático de posicionado de bobina en altura y centrado en línea.

- Automatic centering of the end of the band.

- Paper or Plastic film application:

- From top and bellow of the metal surface.

- Slitting shears:

- Automatic slitter quick change.

- Automatic exchange system for separating shafts.

- High axial accuracy cutting system.

- High number of cuts on slitting shear with minimum deflection and without cutting burr.

- Loop pit:

- Automatic metal strip threading system from the slitting shear to recoiler, through the tension unit.

- Automatic strip loop control.

- Automatic transfer of the band.

- Braking and Tension Unit:

- Configuration:

- Combination according strip type of metal and surfaces. High winding accuracy system by means of movable tension unit and automatic control system.

- Special braking system for gentle metal surface treatment as stainless steel, aluminium, coatings and so on.

- Recoiler:

- With and without use of slit coils separating system.

- Line Automation:

- Custom tailored high - medium- low automation requirements.

- Modem on- line teleservice.

- Coil Packaging Line:

- Without production interruption.

- Circumference banding on recoiler.

- Custom tailored packaging line lay-out.

- Packaging systems manual, semiautomatic and automatic.

More information about Slitting lines :

Metal coil slitting, cut to length lines and packaging and stacking lines

- Offices: Avenida de Navarra 24 - 20013 San Sebastian - Guipuzcoa - España. Tel:(+34) 943.209.223 - Fax: (+34) 943.209.223

e-mail:cinser@cinser.eu - Manufacturing Plant - Factory: Avenida de la Industria, 56-58, Carretera M-413, km 1,2 - 28970 Humanes de Madrid - Spain. Phone: (+34) 609.484.285 - Fax: (+34) 916.900.735

e-mail:jorge@cinser.eu